Traditional quality inspection relied on human eyes scanning products for defects—a process inherently limited by attention span, fatigue, and the physical impossibility of detecting microscopic flaws at production speed. Manufacturing evolved to accept statistical sampling as inevitable compromise: inspect some products thoroughly rather than all products adequately. The Computer Vision system (https://quant-robotics.com/solutions/computer-vision) shatters this compromise entirely, delivering 100% inspection at production speeds with detection capabilities exceeding human perception by orders of magnitude. By giving industrial robots computational intelligence to interpret what they see, modern vision systems transform quality control from reactive gatekeeping into proactive defect prevention.

The Technology Behind Machine Vision

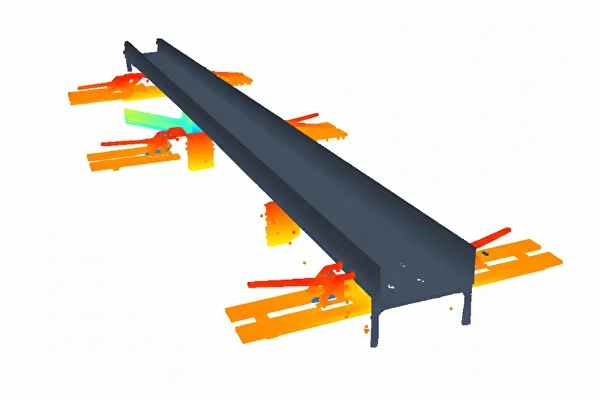

Modern computer vision systems don't simply capture images—they construct detailed three-dimensional models and analyze them against specifications with mathematical precision in real-time:

- 3D laser scanning captures geometry with micron-level precision. Unlike 2D cameras seeing only surface appearance, laser profile sensors project structured light onto components, measuring actual three-dimensional geometry. These systems capture length, width, height, depth, and hole dimensions with accuracy measured in thousandths of millimeters—resolution impossible for human visual inspection.

- 4K+ resolution reveals surface defects invisible to naked eye. High-resolution imaging detects microscopic cracks, porosity, surface contamination, and finish inconsistencies that escape human detection even under magnification. What appears acceptable to visual inspection may reveal significant flaws when analyzed at sensor resolution levels.

- Real-time processing analyzes thousands of data points instantly. Advanced algorithms compare captured geometry against CAD specifications, calculating dimensional deviations, identifying anomalies, and making accept/reject decisions faster than products move down production lines.

- Machine learning improves detection accuracy over time. Vision systems learn what constitutes defects versus acceptable variation by analyzing thousands of samples. This trained intelligence catches subtle patterns that experienced human inspectors might miss while reducing false positive rates.

The transformation isn't merely about speed or consistency—it fundamentally expands what "quality control" means by detecting defect categories previously undetectable until failure occurred in service.

Integration: Vision Systems as Robotic End-Effectors

The most powerful vision implementations integrate directly onto robotic arms as intelligent end-effectors. This mobility transforms static inspection into dynamic quality assurance that adapts to complex geometries:

- Robot-mounted sensors access complex geometries completely. Fixed inspection stations miss defects on hidden surfaces or irregular shapes. Vision systems mounted on robotic arms navigate around components, capturing data from every angle and ensuring no surface remains uninspected regardless of geometric complexity.

- Optimized scanning paths maximize efficiency and coverage. Intelligent software plans optimal robot trajectories that capture complete component geometry in minimum time, balancing thoroughness against cycle time requirements. These paths ensure consistent coverage while maintaining production speeds that make 100% inspection economically viable.

- Environmental adaptation maintains accuracy across conditions. Manufacturing environments vary—lighting changes, temperature fluctuations, vibration, and contamination affect measurement accuracy. Integrated vision systems automatically compensate for environmental factors, maintaining calibrated precision regardless of surrounding conditions.

- Immediate feedback enables real-time process correction. When vision systems detect systematic deviations—dimensions drifting toward specification limits or patterns suggesting tooling wear—they trigger immediate alerts. This real-time feedback allows process adjustments before defects occur rather than discovering problems through post-production inspection.

This integration creates closed-loop quality systems where inspection data directly influences production parameters, transforming quality control from passive measurement into active process optimization.

Beyond Inspection: Vision-Guided Manufacturing

Computer vision's impact extends far beyond detecting defects. Modern systems guide manufacturing processes themselves, using visual data to direct robotic operations with precision impossible through pre-programmed movements alone:

- Component identification and positioning for assembly. Vision systems examine incoming parts, identify which component sits in which orientation, and calculate exact coordinates for robotic pickup. This visual guidance eliminates the need for precisely fixtured part presentation, allowing robots to handle components placed randomly.

- Micrometer-accuracy placement in complex assemblies. Vision-guided robots position components with extraordinary precision by visually confirming locations before final placement. This capability proves essential in assemblies with tight tolerances where accumulated positioning errors would cause interference or performance degradation.

- Adaptive welding based on actual joint geometry. Rather than following blind pre-programmed paths, vision systems scan actual weld joints before welding begins, detecting gaps and alignment variations. Welding parameters automatically adjust to actual conditions rather than assumed ideal geometry, dramatically improving joint quality.

- Automated sorting and routing based on measured characteristics. Vision systems measure components as they pass, automatically routing them to appropriate destinations based on actual dimensions or detected features. This intelligent sorting enables flexible manufacturing where single production lines handle multiple product variants without manual changeovers.

These applications demonstrate how computer vision transforms from quality inspection tool into fundamental manufacturing enabler—the sensory foundation upon which adaptive, intelligent production systems operate.

The Intelligent Manufacturing Future

Computer vision represents more than incremental quality improvement—it fundamentally redefines manufacturing's relationship with variability and defects. Where traditional approaches accepted statistical sampling and inevitable defect rates, vision-guided systems achieve 100% inspection at production speed while simultaneously guiding operations with precision exceeding human capability. As product complexity increases and tolerance demands tighten, the gap between vision-enabled and traditional manufacturing only widens. Forward-thinking manufacturers partnering with specialists like robotics solutions provider Quant Robotics recognize that computer vision isn't auxiliary quality equipment but foundational infrastructure for competitive manufacturing in markets where perfection becomes the baseline expectation.

140

140  ~4.5 мин

~4.5 мин